Product

Full Automatic Aluminum Foil Sealing Machine (With Conveyor)

LK-400C Full Automatic Aluminum Foil Sealing Machine (With Conveyor)

Product ID: LK-400C

What is “Induction aluminum foil sealing machine”?

Induction Aluminum Foil Sealing Machine is used for PP, PE, PET, PS, ABS, HDPE,LDPE and glass bottles, which utilizes electromagnetic principle to produce instant high heat to melt aluminum foil that then adheres to the opening of the bottles, reaching the aim of wet-proof, leakage-proof, mildew-proof and extending preservation time.

A common type of inner seal is a 2 pieces inner seal which leaves a secondary seal inside the caps once the induction seal has been removed. This is commonly used where issues of leakage are a concern. Another option is the single piece inner seal where once the induction seal is removed there is no liner left in the closure. You can also choose from seals that have a pulltab or ones that have a peelable seal leaving no residue on the bottle. You must be certain that the liner is compatible with the bottle material.

Specifications:

■ Max. Power: 2500W

■ Voltage: 220VAC 50/60Hz, Single phase

■ Weight of Generator: 24.20 kgs

■ Dimensions of Generator: (L)300mmx(W)300mmx(H)470mm

■ Weight of Sealing head: 6.20 kgs

■ Dimensions of Sealing head: (L)500mmx(W)200mmx(H)123mm

■ Sealing Range: 20-60mm (Other sealing ranges are available on request)

■ Operating Frequency: 60~100 KHz

■ Variable Speed Conveyor

▲ Conveyor Length: 1.5 meters.

▲ Conveyor Belt: Width 100mm plastic chain.

▲ Loading/Conveyor Height: 800±50mm from floor.

▲ Speed of Conveyer: 0-12m/min. (Adjustable as required)

▲ Standard model can be custom-made to meet the requirement of any bottle specifications.

Recommend Optional Equipment

- Automatic Filling Machine

- Automatic Capping Machine (Model No.:LK-780C or LK-790C)

- Missing Foil Detection Module (Model No.: LK-100)

Features:

■ No complex parameters need to set.

■ High efficiency with low power consumption.

■ Intuitional and human design of control interface.

■ Easy learning and operating for un-technique user.

■ Locking mobile cart and leveling feet for easy move

■ Heavy Duty 304 Stainless Steel / Aluminum alloy Frame.

■ Loading/Conveying Direction: Left to right if facing front of machine.

■ Unique air-cooled design, No water changes and no pump breakdowns.

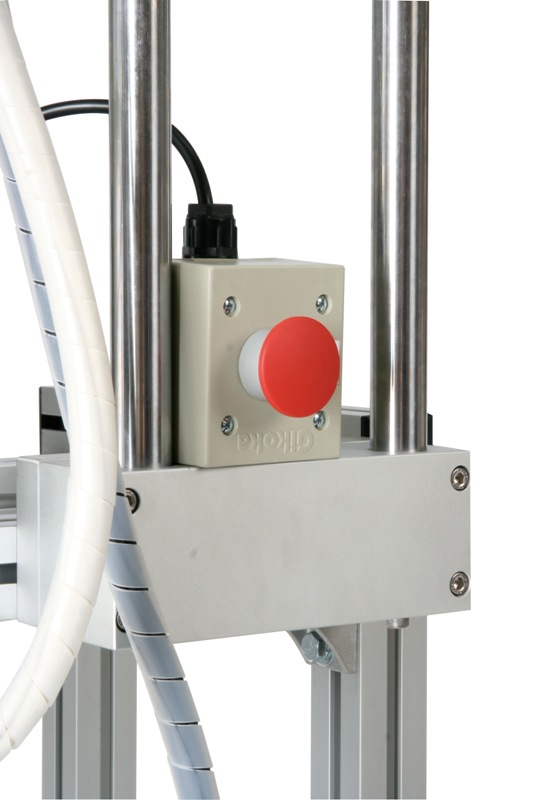

■ Modular component design, Dependable & reliable SMD technology. With a warning alarm.

|

Order Information:

- Minimum Order: One Set

- Branded Product, Buyer's Label Offered

- FOB: Any Port of Taiwan

Contact Detail

| CEO: | Mr. Kevin Shih |

| Address: | No. 20, Lane 600, Xinguan Road, Puxin Township, Changhua County 51343, Taiwan (R.O.C.) |

| TEL: | 886-4-8281838 |

| FAX: | 886-4-8281837 |

| Email: | sales@likai-tech.com |

| URL: | |

| ZIP: | 51343 |